Supply Chain Design

Rising costs, delayed deliveries, and inventory in the wrong place?

Supply Value supports organizations in designing and building a future-proof logistics network that delivers control over costs, inventory, and delivery performance. Using data-driven scenarios, we help achieve up to 25% lower logistics costs, up to 20% higher delivery reliability, and up to 40% less capital tied up in inventory.

From strategy to implementation: We make your supply chain work! Smarter, more reliable, and future-ready.

A Supply Chain That Works – Today and Tomorrow

The pressure to become more sustainable is mounting. Regulations are tightening. Innovations such as electrification, automation, and data-driven logistics are accelerating. Falling behind is not an option. At the same time, your network is becoming increasingly complex: multiple locations, diverse product flows, labor shortages, all while customers demand ever-higher performance.

Has the efficiency of your operations declined? Are you consistently missing your (strategic) KPIs? Are you unsure about the impact of these developments on your business? More importantly, do you know what needs to change to stay successful?

Supply Chain Design provides the answer.

By taking a strategic view of your logistics infrastructure, we help you build a future-proof network. What locations are essential? How can we move goods more efficiently? What does electrification mean for your routes? How does the network support your growth strategy, sustainability goals, and customer expectations?

Your logistics network is constantly evolving. By regularly revisiting and redesigning your logistics network, you lay a solid foundation for an agile, efficient, and forward-looking operation that aligns with your business strategy.

Various scenarios for the logistics network.

Electrification Demands a New Logistics Network Design

With the introduction of zero-emission zones in Dutch cities, the shift to electric vehicles in logistics is becoming a reality. But electrification goes beyond simply replacing vehicles. It requires a strategic redesign of your logistics network.

Regulations are tightening, supply chain partners are demanding higher sustainability standards, and customers expect transparency. Many logistics networks are not yet future-ready. Routes don’t align with charging infrastructure, legacy vehicles no longer meet the new requirements, and old delivery patterns aren’t compatible with your new fleet. This increases the risk of fines, delays, and operational disruptions, potentially resulting in lost customers.

Want to know what this means for your organization? Download our whitepaper on the implementation of zero-emission zones and discover the key requirements for compliance.

Tool: Zero Emission Zone Checker

This is an interactive dashboard. View it in full screen by clicking the arrows in the bottom right corner.

Wondering if your vehicle will still be allowed into the city?

The rollout of Zero Emission Zones (ZEZ) has begun across Dutch cities, but regulations vary significantly by municipality and vehicle type. While some cities won’t impose restrictions until 2030, others will already ban certain vehicles starting in 2025.

This interactive tool gives you instant insight into where and when your vehicle is still permitted.

Select your vehicle type and the cities you operate in to discover what lies ahead for your fleet. Avoid surprises and plan smart for a zero-emission future.

Logistics Mergers: From Dual Operations to One Powerful Network

Following a merger, many logistics organizations continue to operate parallel systems, often the result of legacy structures. But this setup limits economies of scale, increases costs, and leads to inefficiencies.

A merger offers the opportunity to fundamentally redesign your logistics model. Not just by integrating organizational structures, but by taking a strategic look at the entire network: people, assets, infrastructure, and processes.

Without proper logistics integration, costs will continue to rise, flexibility will decline, and the risk of delays, errors, and downtime will grow. Redesigning your logistics network after a merger is no longer a luxury; it’s a necessary step toward a resilient and future-proof operation.

Supply Value helps you analyze, design, and implement a smart logistics network. Data-driven, pragmatic, and aligned with your strategic goals. Together, we build one powerful, agile, and efficient logistics network during and after the merger.

Whitepaper: Logistics Improvement Projects

Why do some Logistics Projects succeed, while others fail? What separates a successful logistics project from one that stalls or fails?

In our whitepaper, you’ll gain unique insights from dozens of projects across both the public and private sectors. Through interviews and data analysis, we reveal the critical success factors, and the common pitfalls.

Looking to improve logistics processes, reduce costs, and boost performance? This whitepaper gives you the knowledge to make better decisions and steer your projects with greater focus and impact.

Our solution: A single logistics model that works

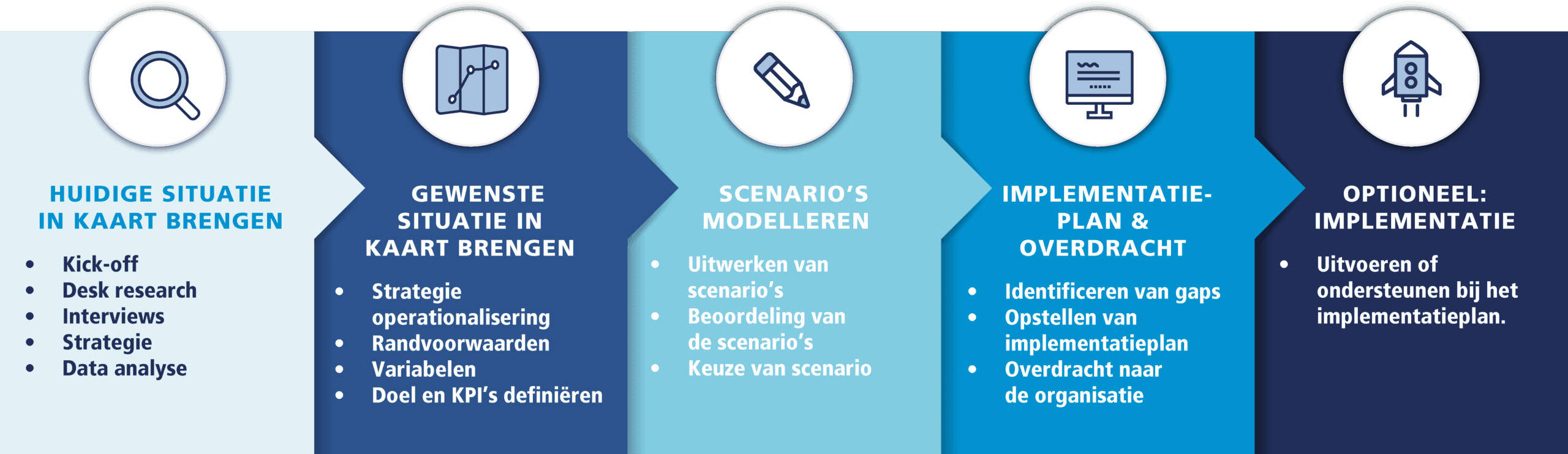

We help you design and implement a future-ready logistics network. Our approach includes:

• Mapping your logistics network and current assets: Waar speelt uw operatie zich af? Where is your operation active? What vehicles, transport modes, locations, and personnel are currently in use?

• Assessing future readiness: We identify where and how your current network falls short of being future-proof or misaligned with your strategic goals.

• Data analysis and scenario modelling: Using quantitative methods, we develop scenarios that lead to a more efficient network. Depending on the scenario, we can reduce transport and inventory-related costs by up to 10% while ensuring future readiness.

• Implementation and adoption: By involving your teams in the change process, we create buy-in and ensure the successful implementation of the new model.

Our approach delivers a clear strategy, a concrete implementation plan, and the right KPIs to make your logistics network resilient and future-proof.

Curious which logistics network best fits your organization? Request a free consultation and discover how we can make your logistics agile and efficient — aligned with your unique strategy.

How we create impact for our clients as a B Corp

RELEVANT INSIGHTS

Whitepaper: Electrification and zero emission zones: threat or opportunity?

In early 2025, the first zero-emission zones came into force in major Dutch cities, despite political hesitation. But while policy lagged, the market moved forward. Electric vehicles are now a reality for many companies, and OEMs are racing to extend battery range....

Whitepaper: Logistics Improvement Projects

Logistics improvement projects play a crucial role in enhancing efficiency, reducing costs, and improving the overall performance of organizations in both the public and private sectors. These projects often address challenges related to warehousing, transport, or...

Whitepaper: Machine Learning – Challenges and Opportunities

Machine learning is an important part of artificial intelligence: we encounter it every day. It is developing at lightning speed, while companies have access to more and more data. In recent years, we have seen how powerful data can be. Combined with machine learning,...

Supply Value

At Supply Value, we understand the complexity of logistics networks — and how essential it is to maintain control over cost, performance, and sustainability. We specialize in designing and optimizing logistics networks that work — today and tomorrow.

We support organizations in mapping their current networks, analyzing the impact of innovations and changes, and developing data-driven scenarios to create a future-proof logistics network.

No off-the-shelf advice, but tailor-made solutions based on your strategy, objectives, and data. We combine deep expertise with a pragmatic approach, delivering solutions that are supported across your organization — from analysis to implementation.

We make strategy work!

Happy clients

Curious how Supply Value can help your organization?

Fill out the form below to book your free consultation.

"*" indicates required fields

Anke Creuwels

Senior Consultant

Maurits van Zoeren

BU Manager Supply Chain & Operations

Niek Wattel

Senior Consultant

Expert in logistics network optimization and data-driven decision-making, with a proven track record of delivering €15M in cost savings.

Phone

+316 29 32 25 63