Best Value Procurement

Best Value Procurement (BVP) is an innovative procurement methodology based on procuring and realising the highest value for the lowest price (best value). BVP offers clients a high(er) predictability of the end goal expressed in cost, time and quality with minimum effort and control on the part of the client. BVP offers optimal opportunities for contractors to showcase their expertise.

What is Best Value Procurement?

BVP can be applied in both the private and public sector. In the public sector, the method can be incorporated within the (European) procurement law framework whereby the best supplier is selected on the basis of the Most Economically Advantageous Tender (EMVI). BVP is characterised by the client defining the goals of the project, without the client prescribing (in detail) how these goals should be achieved. So, yes: specify the what-question, but not (or as little as possible): prescribe the how-question. This is left to the suppliers who are experts within their field and can best come up with (innovative) solutions.

Value Process

- Preparation of the procurement process: The BVP procurement process should be well prepared. The project team should have knowledge of the BVP methodology, or be trained (internally) to do so. Central to the preparation is finding out the project objectives. These should be drawn up as abstractly as possible. In this phase, the Request for Proposals and associated issues such as the weighting factors are drawn up.

- Publication of the Request for Tender: In this phase, a Market Information and BVP meeting is held to explain the tender and BVP methodology. Also at this stage, the specifications are published, the Nota van Inlichtingen (NII) round(s) take place and interested market parties tender.

- Selecting: Selecting is finding the EMVI, the most economically advantageous tender, is done using the award criteria with associated weighting factors. Best practice in BVP is to weight price 20% and quality 80%. The 80% is structured as follows:

- Performance substantiation: 20%

- Planning: 5%

- RAVA plan (Risk and Opportunity File): 25%

- Interviews: 30%

Image 1, Select BVP

4. Concretisation: With the best-scoring supplier , the EMVI found, the Concretisation phase is started. In this phase, the supplier has to elaborate and thus clarify his tender. This is necessary because in the first phase the suppliers have only outlined their tender. In this phase, the chosen supplier has to elaborate its tender in detail.During this phase, the supplier prepares a risk file, describing the unique risks that this supplier sees for the project and the risks that the competition has defined, and the management measures that the supplier takes for all defined risks to minimise the occurrence of risks. Also, the value-increasing options chosen by the client are detailed by the supplier at extra cost. If the detailed elaboration is fully satisfactory to the client, the contract is actually awarded.

5. Execute: During the execution phase, the supplier is made responsible for managing the project. This allows the supplier to be as close as possible to the project and to identify and adjust deviations from the lead time, the available budget and the quality of the final delivery at the earliest possible stage. During project management, the supplier uses the risk file as drawn up in the previous phase. A risk that occurs, whether or not it is defined in the risk file, is included in the Weekly Risk Report sent to the client.

Advantages of BVP

Applying BVP in your procurement or tendering process has a large number of advantages. We have listed the biggest advantages for you:

- Application of BVP has a positive impact on the performance of the procured project in terms of lead time, costs and customer satisfaction. See research on European Tendered ICT projects conducted by Supply Value in collaboration with Radboud University Nijmegen. In addition, see overall results of application of BVP in 1000 projects worth $4.7 billion (pbsrg.com/about/results; Sullivan, Kashiwagi, & Chong, 2007; Kashiwagi, 2011):

• Customer satisfaction of 98%;

• Minimisation of deviations in cost and lead time;

• Minimisation of risks and project management by the client up to 90%;

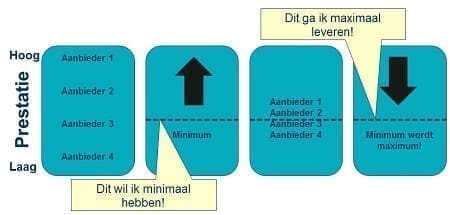

• Increased supplier revenues up to 100% without increasing project costs. - Lower Total Cost of Ownership than traditional (procurement) methods where price is decisive. A traditional procurement method usually involves formulating specific requirements in the form of minimum norms, standards and quality criteria. With these, the client wants to secure a certain minimum level of the purchased project. In practice, however, this appears to have the opposite effect. All suppliers focus on the defined minimum in order to keep the price, which is decisive for awarding the contract, as low as possible. As a result, the minimum desired quality level has also become the maximum level that suppliers will deliver, see Figure 2.

- In addition, defining minimum requirements enables poorly performing suppliers to compete successfully for the award of the project. They can win the contract by meeting all the detailed prescribed conditions. Moreover, it removes the competitive advantage of well-performing suppliers. They can perform better than the defined minimum. This is also clearly visible in Figure 2.

Image 2, minimum conditions

- BVP requires only outline bids from all bidders in the 2nd phase when finding the EMVI. This leads to advantages for the suppliers and for the client. The suppliers save transaction costs for detailing their tender. This saves the tenderers a lot of work at a stage when the chances of being awarded the project are still relatively low. In total, each tenderer’s tender is only a few pages, in which the tenderers are responsible for distinguishing themselves from their competitors. In addition, tenders are assessed for dominant differences by your organisation. This allows the client to identify the best bidder with little energy. This provider should detail the entire bid in the 3rd stage, allowing the client to check whether this provider can deliver on all its promises. If it does, and there are no more concerns on the part of the client, the project is awarded.

- The generic nature of BVP makes it widely applicable, namely for any product or service being outsourced where the market logically has more knowledge than the client, the outsourcer.

Are you interested or want to know more about Supply Value?